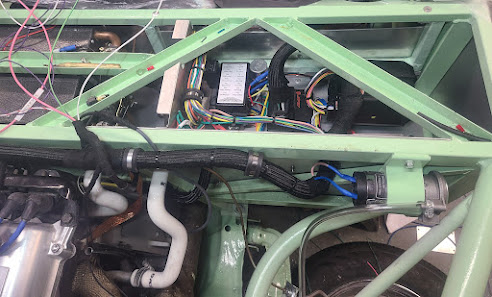

Moving along with the wiring job. The manual for my Microsquirt ECU lists some wiring "best practices," one of which is to work all in one direction; either from the ECU outward, or from the terminal ends back to the ECU. Since I started from Grand Central Station (the compartment where I put the ECU, power distribution block, fuse box, and relay box) it made more sense to work from there outward.

Above, upper right is Grand Central Station. At this stage I've brought the wiring harness through the firewall and along the frame rail, hooking into the horn air compressor (middle right, pink and blue wires), O2 sensor, and main ground point along the way.

Another "best practice" is getting all the wires into their general area before trimming and hooking them up. I forgot about this one with no ill effects at the horn compressor or O2 sensor, but the ground wires got a little untidy so I plan to follow the instructions henceforth. The ignition wires (upper left) go in this general neighborhood but I moved on without hooking those up yet.

Time Away

Wow it's been a long time since I've updated the blog. Three weeks between the above and me typing now. Part of that has been time for things other than the project car. Over Fall break, I went on a father-daughter trip to Chicago with Jane the Bear. She's gotten heavily into cooking lately, and we had some great meals and some inspiration for new meals to try at home.

She's also an Animal Whisperer with a fondness for marine mammals, so time at the Shedd Aquarium was de rigueur. We also saw a performance by Blue Man Group which was fantastic.

Most of the unusual cars I saw in Chi weren't super interesting to me - like recent model supercars. Yes, nice car, but doesn't really excite me much. But I had to snap a pic of this Ford Crestline convertible. The car has either been very well kept or very thoroughly restored (maybe a combination of the two). These were made 1952-1954 and came with either a straight six or a flat head V8. Not a high performance car either way, but what a nice ride.

I Cannot Work Under These Conditions!

Another distractor from wiring has been a long overdue garage reorganization project. One of the problems has been my random collection of small mis-matched toolboxes that take up a lot of space without providing a commensurate level of storage and accessibility. I've been looking for deals on a new toolbox and finally hit on one.

I really prefer not to use top chests - I like to keep the top of the toolbox open as a work space (or, admittedly more often, a pile things up space). This flat top roller box is from Harbor Freight - not sure if y'all Brits have Harbor Freight; it's a chain store full of discount tools from China. Professionals tend to turn up their noses at HF offerings, and no doubt, if you're using a tool every day there are higher quality options. But if you're going to use a tool once, then maybe once again 5 years from now, it's a pretty decent option. And for most things they have a higher-quality line to supplement their cheap-as-possible line. HF is phasing out this "medium-quality" series of tool boxes so they're all on clearance pricing and - even better - the unpopular colors are discounted even more. The nearest store with this massively marked down orange box was 90 miles away in a small town that conveniently happened to be on the way to Chicago. So I came home from Chi with a new tool box and have been re-organizing ever since. This will be much more satisfactory than my previous arrangements.

I can't say I have actually cleaned and organized the garage. But I have cleaned and organized one corner of the garage, and I have cleaned and organized the storage spaces. In my past experience this is the key to cleaning and organizing anything - if the storage spaces don't work, any cleaning improvement will be superficial and temporary. Either that, or this has all been an excuse to buy a new toolbox.

Another Not-Wiring Detour

A couple weeks ago Miata John dropped by to graciously help with bleeding the brake and clutch lines.

We ran in to a problem with the clutch master cylinder - or maybe it's the clutch pedal assembly. For whatever reason the pedal was bottoming out against the footwell before the plunger went far enough to disengage the clutch. I think there may be some kind of UK/RHD vs US/LHD thing going on here.

The UK pedal assembly has these bosses at the base of the master cylinder mounting studs. These protrude from the firewall when installed. I am told that this normal, and in the RHD arrangement, the master cylinder sits atop these bosses. On the US/LHD cars I've looked at, the clutch master cylinder sits flush against the firewall so something must be different. Having the master cylinder teetering atop these bosses just didn't look right to me on first assembly, so I made the black spacer (above right) to fill the gap (this is an ABS 3d print; I've subsequently re-made this in stainless steel). There isn't much of the clutch pedal plunger extending beyond this - probably why I couldn't get the clutch to disengage. At first I blamed the spacer, but even without the spacer, the MC bolts up to the bosses so it doesn't get any closer to the firewall. The plunger has some length adjustment but not enough.

So I ordered a length of m8 x 1.0 all thread rod, took it out to Pops Racer's shop, and chucked it up in the lathe to make a longer clutch plunger. In the above video, watch the hand crank in the left lower middle of the frame. Look, Ma! No Hands! I always thought the auto feed thing was cool.

It's tricky to turn any piece that is this long and this thin. The chuck holds the left end on center and the tail stock takes care of the right end, but things can get wobbly out in the middle. Instead of cutting, the tendency is for the turning tool to just push the work piece out of the way - which makes for some very ugly machining. I had to turn this down in very small bites and it still needed some touch up with a file to look not-hideous in the middle.

OEM clutch pedal plunger below, extra long version above. I know this is longer than necessary; my idea is to cut it down until I get the right length.

Another not-wiring job was sorting the brakes on my lovely and long-suffering wife's Odyssey van. I had help with this from Taylor the Mighty. After playing sous-chef to me on the left front, Taylor did the right front with essentially no help from me (she had a hard time getting 95 ft-lb torque in a confined space - but got it easily where she had some room to work with).

So, progress report: I have all the wires roughed into their general positions out to the end of the harness. Now I'm making the final connections, working my way from the end back toward Grand Central Station.

I do need to get the clutch master cylinder sorted before I go too much farther with the wiring, because it will be easier to do the MC without the wires in the way.

Comments

Post a Comment